The project is to establish a recycling and processing plant for used car, engine and generator oils. The project aims to benefit from used oils that have lost all or some of their properties during operation, as their quality declines, their viscosity changes, their acidity increases, the percentage of mineral impurities and water in them increases, and sediments increase, making them unsuitable for use. The project collects used oils and passes them through manufacturing processes that include filtration, hydrogenation, mixing and refining with the aim of converting them back into usable oils. The project products are recycled oils, and are divided into: (refined oils – gasoline engine oil – diesel engine oils – hydraulic engine oils).

To establish this factory, it is essential to seek a specialized company to conduct a feasibility study for a used oil recycling plant, and this is where Mashroo3k stands out to take on this task. Its team analyzes and studies the market from various angles, revealing a strong demand for the project’s products, which include recycled oils such as refined oils, gasoline engine oils, diesel engine oils, and hydraulic oils. The produced oils are divided into three main categories: light base oil (150 SN), medium base oil (300 SN), and heavy base oil (500 SN).

This project plays a significant role in protecting the environment by recycling waste oils that would otherwise contribute to pollution. The manufacturing process relies on advanced technology and high-quality standards, supported by skilled and distinguished technical and administrative teams. The factory offers its products at competitive prices, targeting sectors such as factories, technical companies, smelting furnaces, oil retailers, and fuel stations. The factory aims to capitalize on the growing demand for its products in target markets and to capture a significant share of the supply-demand gap.

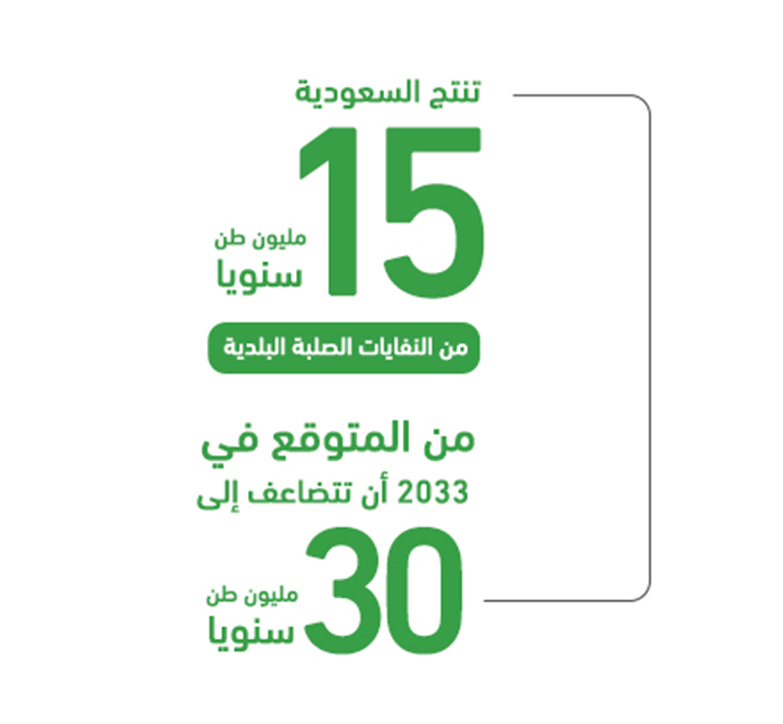

In recent years, Saudi Arabia has turned its attention to the recycling sector, recognizing its importance in achieving the goals of Vision 2030 and its potential to drive the economy towards sustainable development. In 2017, the Saudi Investment Recycling Company (SIRC) was established with the support of the Crown Prince, aiming to save billions of riyals lost annually from the Kingdom’s treasury due to the lack of focus on recycling industries. These lost funds have been approximately estimated to range between 30 billion and 70 billion SAR.

To reassure our clients about investing in this sector, we will present here the most important indicators and results of the sector according to the latest statistics available to us:

Mashroo3k affirms that the volume of waste in Saudi Arabia now exceeds 45 million tons annually. With the Kingdom determined to increase the recycling rate from 1% to 80% by 2035, the company believes that investing in this vital sector will be highly profitable.

Regarding the prospects of the recycling and energy industry, we can mention the following:

Mashroo3k for Economic Consultancy and Market Research emphasizes that recycling is one of the promising sectors in Saudi Arabia, and its projects will present genuine investment opportunities, especially as the Kingdom moves towards a green economy. Environmental preservation has become a top priority for the wise leadership, as clearly reflected in Vision 2030.